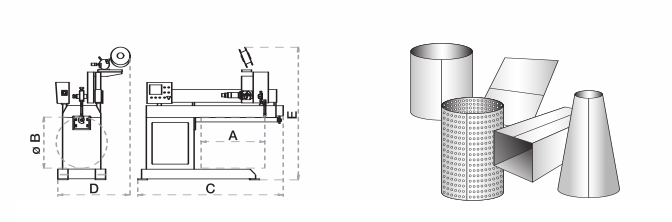

BR - Longitudinal welding plants

BR longitudinal seamers are designed for butt welding of circular/rectangular ferrule or flat sheet with a thickness from 0,5 mm up to 10 mm and lenght from 500 mm up to 6000 mm. The welding technologies suitable are MIG/MAG, WIG, PLASMA and SAW.

The structure of the seamer is designed and built for operator 's ergonomics; the color touchscreen display of the numerical control in installed on a moveable console while the buttons for the bi-manual control are placed in front of the operator, for an easy plant management.

The heart of the system is the ferrule/sheet sheet support, made of a copper alloy for the maximum wear resistance and at the same time due to the pneumatic clamping system realizes the “chill-shunt” effect that is the capacity to absorb and dissipate along the joint the welding heating input to reduce distortion, to guarantee the penetration and to control the burnbacks.

The ferrule/sheet copper support is complete of channels for coolant liquid with flux sensor (optional) and backup protective gas to avoid the oxidation of the welding pool and guarantee the full penetration.

The ferrule/sheet copper support is complete of channels for coolant liquid with flux sensor (optional) and backup protective gas to avoid the oxidation of the welding pool and guarantee the full penetration.

The longitudinal seamer is ccontrolled by N.C. with colors touchscreen display able to manage the following parameters:

- Welding lenght;

- Welding speed;

- Start carriage delay;

- Welding fading end;

- Back-up protection;

- Upper protection;

- Spot welding;

- Opposite spot welding;

- Welding program selection;

- Cold wire (speed, start delay, wire retract at welding end);

- Arc Voltage Control (as a second N.C. axle) only for WIG/PLASMA.

Mecome's welding seamer range.

External longitudinal seamer

External longitudinal seamer is used where it is desidered to weld from the ouside of the ferrule with penetration bead in the inside.

Combination longitudinal seamer

Is designed to join the ergonomic feature of the external one for small diameters and the flexibility of the internal one for big diameters. Combination longitudinal seamer is supplied with a removeable riser which increases the diameter ferrule that can be welded underneath the tabletop to be able to reach with the external welding (in case of high useable length) the minimal welding inner diameter.

Internal longitudinal seamer

Internal longitudinal seamer is designed for application where the diameter of the ferrule to be welded is large. It doesn't employ a conventional support; instead, it is fitted with a sturdy base structure on which the insert holder and the copper support are mounted. The advantage of this design is that there is virtually no limit to the diameter of the ferrule that can be welded. The only limitations are the size and facilities of the building in which the seamwelder is situated.

Elevating longitudinal seamer

Elevating longitudinal seamer is essentially a variation of the combination model. Instead of a fixed height riser, the tabletop and copper support on this model are mounted on support columns on which they can be moved up and down. Movement is effected using a hydraulic cylinder with special fail-safe valves to ensure that the unit remains firmly in position, even in the even of power failure.

BR Auto

This plant represents an important step forward the techniques associated with the seam welding of cylindrical and other regular shaped parts, for companies requiring high volume seam welding out put coupled with minimal operator intervention.

The MECOME range of automatic seam welders is based upon standard products with the addition of a number of features to enhance the loading, alignement, clamping and welding of the part.

The MECOME range of automatic seam welders is based upon standard products with the addition of a number of features to enhance the loading, alignement, clamping and welding of the part.

Benefits:

BR 0130 AUTOBBR 1300 AUTOTo operate the machine, the operator simply pushes the ferrule on to the mandrel, it is guided by guide rails on the sides and on the bottom. From this point, the cycle phases are completely automatic, the alignment and closing of the weld seam is carried out using special hydraulic devices controlled in position by the PLC of the Numerical Control. This is followed by a full automatic, preprogrammed welding cycle. During the welding cycle, the operator is free to load/unload a second seam welder or to prepare parts for the next operation. At the end of the welding cycle, the seam welder automatically releases the welded part and resets itself for the next cycle

MECOME automatic seam welders are designed with safety in mind and, following a short period of training (2 hours), can normally be operated by semi-skilled personnel.

An important feature of MECOME automatic seam welders is the ability to rapidly change from one size ferrule (diameter / length) to another. This is achieved simply by calling up the appropriate welding schedule held in the N.C. memory due to the control in position with encoder of the following 5 axis:

- Axis X longitudinal welding carriage;

- Axis Y lifter raisable movement;

- Axis Alfa radial movement of right clamp;

- Axis Beta radial movement of left clamp;

- Axis Gamma longitudinal movement of zero reference point.

A wide range of accessories is available to enhance the performance of automatic seam welders.

Vertical longitudinal seamer

Vertical longitudinal seamer is mainly designed ferrules with big diameters and small thickness (wine/food storage tanks) so that the production flow requires the axis of the ferrule in vertical position also for the circular welding (thickness of 5 mm maximum with diameter up to 3000 mm). Usually this plant is connected with vertical bending machine and flat table position with column-booms.

BR SERIES: tech data

| Saldatura esterna |

Lunghezza utile di saldatura A |

ø min. virola mm |

ø max. virola mm B |

Lunghezza totale mm C |

Larghezza totale mm D |

Altezza totale mm E |

Peso kg |

| A | B | B | C | D | E | ||

| BR500 | 515 | 70 | 800 | 2000 | 800 | 1850 | 1040 |

| BR600 | 618 | 70 | 800 | 2100 | 800 | 1850 | 1100 |

| BR1000 | 1030 | 80 | 800 | 2500 | 800 | 1850 | 1280 |

| BR1100 | 1133 | 100 | 800 | 2600 | 800 | 1850 | 1350 |

| BR1300 | 1339 | 120 | 800 | 2800 | 800 | 1850 | 1500 |

| BR1500 | 1545 | 130 | 800 | 3000 | 800 | 1850 | 2000 |

| BR2000 | 2060 | 160 | 1100** | 3500 | 950 | 2100 | 2450 |

| BR2500 | 2575 | 180 | 1100** | 4000 | 950 | 2100 | 2900 |

| BR3000 | 3090 | 250 | 1100** | 4700 | 1000 | 2250 | 5300 |

| Saldatura est./int. |

Lunghezza utile di saldatura |

øminimo virola mm |

ømassimo virola mm |

Lunghezza totale mm |

Larghezza totale mm |

Altezza totale mm |

Peso kg |

| A | B | B | C | D | E |

||

| BR1500 | 1545 | 1100 | A seconda delle esigenze |

130 | 800 | 1150 | 2100 |

| BR2000 | 2060 | 1100 | 160 | 1000 | 1150 | 2380 | |

| BR2500 | 2575 | 1100 | 180 | 1000 | 1650 | 2900 | |

| BR3000 | 3090 | 1100 | 250 | 1000 | 1650 | 5300 | |

| BR3500 | 3605 | 1100 | 300 | 1050 | 1800 | 5900 | |

| BR4000 | 4120 | 1300 | 350 | 1050 | 1800 | 6300 | |

| BR5000 | 5150 | 1300 | 460 | 1100 | 1800 | 7200 |

<